Adhesives

CAUSE OF FAILURE:

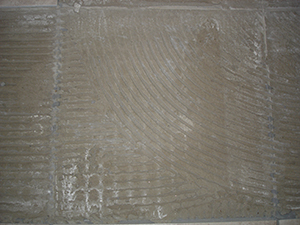

Tile Adhesive stuck to tile, but not the substrate

Poor surface preparation could lead to the tile adhesive not sticking to the substrate. For example, insufficient chipping of substrate such as painted surfaces, gypsum plasters, old bitumen adhesive and waterproofing.

LESSON LEARNT

Chip the surface to at least 80%

Preparing Surfaces

- Mix Basecoat and Keycoat as per pack instructions

- Apply mixture +/- 2mm thick to surface using a block brush

- Allow to dry for 24 hours before tiling

CAUSE OF FAILURE:

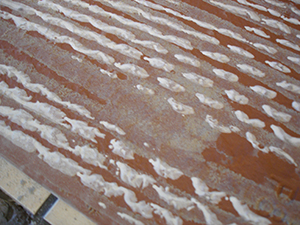

Tile adhesive stuck to the floor but not the tile

- Tiles not clean (tiles may contain dust from manufacture)

- Incorrect bedding

- Skinning

- Using the wrong adhesive

LESSON LEARNT

Chip the surface to at least 80%

Follow the steps below to ensure a sound tiling installation

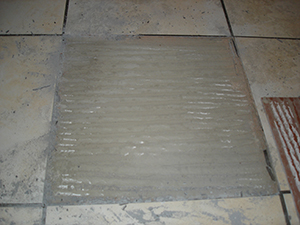

Floor Adhesive Application

- Only use a 20mm notched trowel for consistent bedding

- A 10mm notched trowel is only to be used for small format tiles and wall applications

Bedding Floor Tiles

- Flatten entire tile onto the 20mm bedding in a forward and backwards motion

- This motion causes the trowel lines to ‘break’, minimising voids and improving adhesion

- Use a rubber mallet to tap tiles in place

- Remember to use the appropriate spacers in between tiles

Tile Coverage

- A tile is bedded correctly when the entire under surface is covered with adhesive and there are no trowel lines visible.

- A 20mm notched trowel is recommended to ensure correct coverage on large format tiles

'>

'>